Before any newly designed airplane, chopper or rocket can take flight, it must first go through extensive testing in a simulated environment — and the only place in the U.S. where a full-size plane can go through that sort of test is at the U.S. Air Force’s National Full-scale Aerodynamics Complex (NFAC), an Arnold Engineering Development Complex test facility located at NASA Ames Research Center at Moffett Field in Mountain View, CA. Ames is world-renowned for its cutting-edge work in the field of aerodynamics, and is capable of performing research, development and testing of aerospace equipment that would be next to impossible anywhere else.

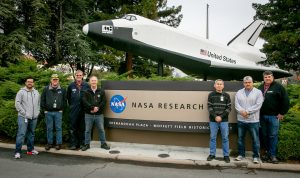

IBEW 1245 members (from left) Sergio Rico, Johnny Connor, Don Ecclestone, Bill VanZuylen, Hiep Khuc, Ron Payne, and Bill Browning work for Jacobs Technology at the NASA Ames Research Center in Mountain View

“Anything that flies — subsonic and supersonic — we’ve tested in our wind tunnels,” said IBEW 1245 member Bill Van Zuylen, who works at Ames in the wind tunnels as an instrumentation technician for Jacobs Technology, which is NASA’s largest support service prime contractor. “I assemble all the sensors that go inside of the model and connect them up to our data acquisition system and actually acquire the data during the wind tunnel test.”

IBEW 1245 is proud to represent the electrical and mechanical workers employed by Jacobs Technology as well as the National Aerospace Solutions, LLC (NAS), a U.S. Air Force contractor that operates on site at Ames. The Local 1245 members at NAS also help to facilitate the testing of new aerospace equipment when it is brought in for a trip through the wind tunnels.

IBEW 1245 members (from left) Bart Aganon, Lex Alday, Craig Morrison and Louie Icari work for NAS at Ames. The wind tunnel is visible in the background.

“We provide the hardware and tech support for a lot of our customers. When they come in with their model, it is our job to facilitate as far as hooking up their instrumentation so that they can communicate with our control room … so they get the raw data that they’re trying to look for,” explained IBEW 1245 member Lex Alday, NAS’s lead instrumentation technician for the NFAC division. “We also install some of the cabling for their gauges to allow them to monitor throughout the wind tunnel testing that goes on, amongst other things. We do fabrication as well, if they need to build any special cables, chassis, anything like that.”

Building and maintaining the massive and powerful wind tunnel systems at Moffett Field is no small job. It takes an extremely skilled, meticulous and knowledgeable workforce to keep these remarkable simulations up and running.

“The Unitary Plan Wind Tunnel Complex has the 11-foot test section which goes from .2 to 1.5 Mach. The 9-by-7 wind tunnel goes from 1.5 Mach to 2.5 Mach,” explained Lead Electrician and IBEW 1245 member Don Ecclestone, who works for Jacobs Technology. “We maintain all the support equipment to make it work; lube system, motors, pressure switches, temperature switches, pressure transmitters, temperature transmitters.”

In an environment geared towards rapid technological advancement, human capital runs the risk of being neglected, which is why the workers at Jacobs and NAS are grateful to have the IBEW on their side. These workers were formerly members of IBEW 2131, a small manufacturing local which struggled for years to provide quality representation with limited resources. In early 2014, Local 2131 officially merged into IBEW 1245, and the 300 manufacturing members have been exceptionally grateful for the support that Local 1245 has provided.

“The union’s been there for us all along ,” said Van Zuylen. “We appreciate their help in negotiations for a new contract, pay raises, wages and health benefits.”

“Cruz Serna, our business rep, he stays in contact pretty well in case there’s ever any issues, which is really nice,” added Ecclestone. “We are a little bit of a smaller group compared to the other [workgroups in Local 1245] … but he makes us feel like we’re just as important as somebody who’s in a 600-member segment.”

The IBEW 1245 members who work on the U.S. Air Force contract for NFAC support are fully funded through the Department of Defense. However, many of the 1245 members who work on the NASA side are being denied access to their worksites due to the government shutdown. If the shutdown continues for much longer, it could drastically impact these 1245 members at Ames, as well as tens of thousands of other workers employed by the federal government.

Due to security clearance issues, members of the general public cannot enter Ames, so regretfully, the Utility Reporter was not able to capture images of our members at work inside the facility. For a glimpse inside Ames, visit NASA’s photo gallery at https://www.nasa.gov/centers/ames/orgs/aeronautics/windtunnels/arc-upwt-multimedia-index.html.

–Rebecca Band, IBEW 1245 Communications Director

Photos by John Storey